Inventory and Warehouse Management

Introduction

In the intricate tapestry of modern business operations, inventory and warehouse management play a pivotal role in ensuring smooth, efficient, and cost-effective supply chain processes. The management of inventory and the seamless operation of warehouses have evolved from basic stockpiling practices to sophisticated strategies that leverage technology, data analytics, and streamlined workflows. This article delves into the significance of inventory and warehouse management, exploring their key components, challenges, and the transformative impact of technology on these critical aspects of business.

Understanding Inventory Management

Inventory management refers to the processes and strategies that businesses employ to oversee the ordering, storage, tracking, and utilization of their goods and materials. The primary objective of effective inventory management is to strike a balance between having enough inventory to meet customer demands while avoiding excessive stockpiles that tie up capital and storage space.

Key Components of Inventory Management

Demand Forecasting

ABC Analysis

Reorder Point

Economic Order Quantity (EOQ)

Safety Stock

Challenges in Inventory Management

Stockouts and Overstocking

Striking the right balance is challenging. Stockouts result in lost sales and customer dissatisfaction, while overstocking ties up capital and incurs storage costs.

Demand Variability

Fluctuations in demand due to seasonality, trends, or external factors can disrupt inventory planning.

Lead Time Uncertainty

Delays in supply lead time can disrupt inventory replenishment schedules.

Warehouse Management: The Nexus of Efficiency

Warehouse management involves the control, organization, and optimization of the movement and storage of goods within a warehouse. With the increasing complexity of supply chains and customer demands, warehouses have evolved from mere storage facilities to strategic centers of operational efficiency.

Key Components of Warehouse Management

Challenges in Warehouse Management

Space Utilization

Optimizing storage space is a constant challenge, especially in densely populated urban areas.

Labor Management

Efficient utilization of warehouse staff while maintaining safety and productivity is essential.

Inventory Accuracy

Inaccurate inventory records can lead to errors in order fulfillment and stockouts.

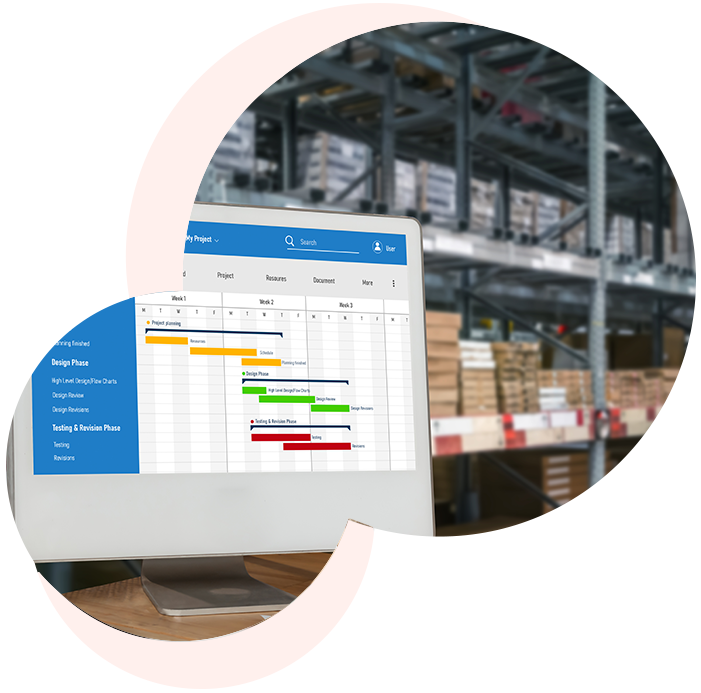

The Role of Technology in Transformation

Both inventory and warehouse management have experienced a revolutionary shift with the integration of technology. From advanced software systems to Internet of Things (IoT) devices, the digital landscape has opened up new avenues for optimization.

Warehouse Management Systems (WMS)

These software solutions streamline various warehouse tasks, from inventory tracking to order processing, leading to increased efficiency and accuracy.

Barcode and RFID Technology

These technologies facilitate accurate and real-time tracking of inventory, reducing manual errors and enhancing visibility.

Automation and Robotics

Automated systems and robotics have transformed warehouse operations by speeding up tasks like order picking and packing.

Data Analytics

Analyzing data from various sources helps in identifying trends, demand patterns, and areas for improvement in both inventory and warehouse management.

Conclusion

In today’s competitive business landscape, efficient inventory and warehouse management are more critical than ever. Businesses that master these aspects of supply chain operations stand to gain not only in terms of cost savings and customer satisfaction but also in their ability to adapt swiftly to market changes. From demand forecasting and inventory optimization to streamlined warehouse operations powered by technology, the pursuit of excellence in inventory and warehouse management continues to shape the success of modern enterprises.